Is biggest best for EV charging?

There is a common belief: the bigger, the better, more powerful EV charging is best for both drivers and landlords. This belief is based on the simple proposition that a more powerful charger gives a faster charging time, and that is what all EV drivers want.

The reality, however, is more complicated.

As charging point operators (CPOs), it is our mission to give drivers what they want: a fast charge, but more importantly, an available charger. Time waiting for a charger can be part of the process and is more stressful than time on a charger. The goal is to charge as many cars as possible at the same time with the maximum useable power level.

Quick conclusions.

- Customer feedback is clear that charger availability is more important than the speed of the chargepoint;

- 300kW chargepoints are held out as the fastest chargers. But these only benefit a small number of luxury EVs. Their main impact is a reduction in the number of chargepoints that can be installed in any location, as a 300kW chargepoint uses power which would serve three 100kW chargepoint, for example;

- For those EVs that can utilise ultra-high-power chargepoints, charging at over 250kW is only sustained for a brief period, resulting in a minimal reduction to charging time.

- Dynamic load-balancing technology is the best of both worlds, allowing super-fast charging speeds and the ability to install more chargers than the grid capacity may allow in a traditional setup.

Not all EVs are equal.

Not all BEVs are created equal when it comes to charging. Some charge at much higher power rates than others and the charging rate is not constant over time. The charging rate slows down as the battery recharges, with some batteries slowing sooner than others.

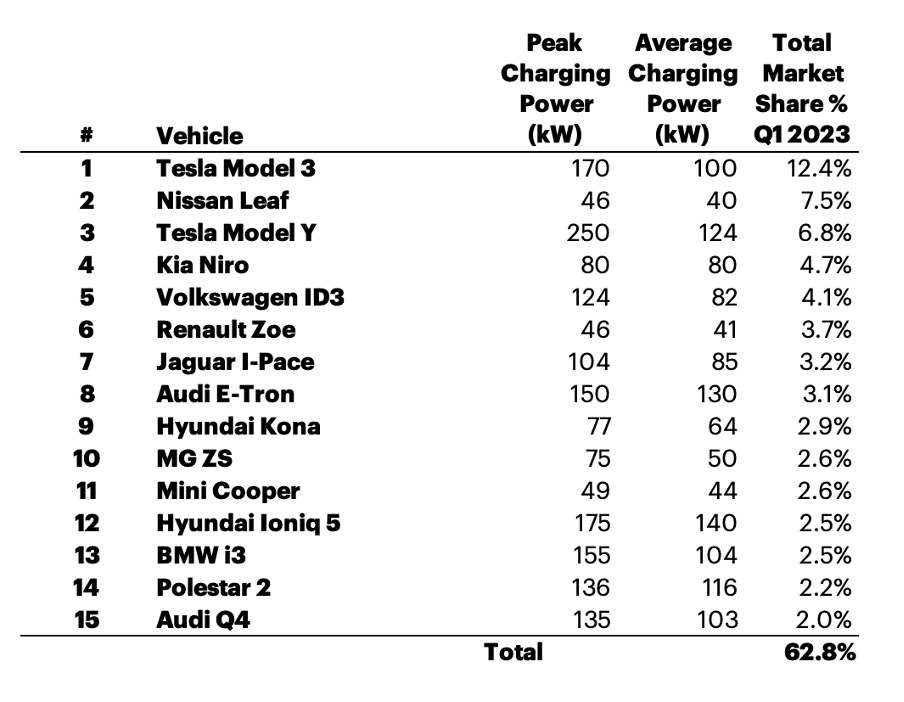

There are large differences between the average and peak charging rates for different cars.

[Sources: Department for Transport Vehicle licensing statistics, Q1 2023, EV-Database]

The table above shows the listed maximum charging power for the 15 most popular BEVs on UK roads at the end of March 2023. This shows that the peak ranges from 46kW through to 250kW with the average peak rate sitting around 120kW. This table also shows that the average charging rate whilst charging the battery from 10-80% is noticeably lower than the peak rate.

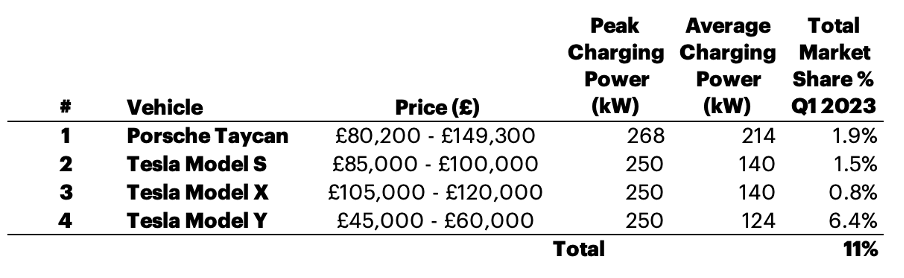

Some of the higher-priced, performance cars can charge at even higher rates, as shown in the table below. These cars, however, only represent 9% of the overall UK market.

[Sources: Department for Transport Vehicle licensing statistics, Q1 2023, EV-Database]

The stated peak rates are only achieved under certain charging conditions (battery state of charge, temperature, etc) and typically for a very short period, usually a couple of minutes, with the charging power declining throughout the charge cycle.

For the above reasons, the peak rate is somewhat academic in the real world. The average charge rate (ACR) is more relevant to everyday EV charging: the average power the car can take over a typical charge cycle. A recharge from 10% to 80% SOC is often used for this purpose as charge rates drop sharply once the battery reaches around 80% charge.

Of the 15 most popular EV models in the UK shown above, the average ACR is around 87kW and no model has an ACR greater than 140kW. This shows that the charging demands of most BEVs would be more than satisfied by a 150kW chargepoint.

As we see from launches of vehicles such as the Hyundai Ioniq 5 with 800V charging capability, there is a valid question whether the superior high-power EV charging technology seen in vehicles such as the Porsche Taycan will trickle down to mass-market vehicles in the next 5 years. However, the major OEMs have indicated that the expense and production platform changes involved mean that this technology will not be featured in mass-market (<£50k) EVs for some time, if ever. This is reflected in Table 2 when looking at the various Tesla models available. While each of the S, X and Y models have a peak rate of 250kW, the competitively priced Tesla Model Y has a lower average charge rate than the S and X.

EV Driver Desires.

As more and more EVs hit the road, drivers have made it clear that the most important thing is the availability of chargepoints. This is not just an increased number of locations, but also more chargepoints installed at each location, giving drivers the confidence that they will be able to get a charge when they arrive at a site. Drivers would rather wait on a charger (i.e. while charging) than wait for a charger (i.e. queuing), within reason of course. In short, more chargers is better. This leads to a key real-world issue: the availability of power to each site.

Power - not quite everywhere

Unlike petrol and diesel, electricity is all around us.

However, the grid infrastructure that serves most roads and buildings is a ‘Low Voltage’ network that can typically only allow the installation of up to two 50 – 75kW chargepoints.

To install high power chargers (HPC), or a ‘hub’ of multiple rapid chargers, requires the installation of a new substation onto the ‘High Voltage’ network, which can cost several hundred thousand Pounds.

Limitations on the power supply to an EV charging site is an important consideration in charger choice.

Supplying the many.

A theoretical example is a site where the maximum amount of available power is 1.6MVA. Here, the different charger configuration options include:

- 4 X 300kW chargepoints

- 8 x 150kW chargepoints

- 12 x 100kW chargepoints

- 24 x 50kW chargepoints

…and so on

The first of these site configurations, with all 300kW chargers, could satisfy four Porsche Taycan drivers if the chargepoints are available. However, assuming the Porsche can utilise the charger, the car will only use the 270kW peak power for around 2 minutes, before dropping to circa 200kW. The ACR across the whole session would be 197kW, meaning that 103 kW of available power is wasted – across the 4 charging bays this spare 412kW could have seen an extra 4-8 rapid chargers installed!

As mentioned above, the average peak charging rate for the top 15 most common EVs in the market is around 118kW. Thus most cars will charge at their average peak charge rate by 100-150kW chargers.

A site with 8 to 12 100-150kW chargers will satisfy more drivers more of the time.

The benefits for the Porsche, or the few other high end-cars capable of using ultra high-power charging, are quite limited in practice with overall dwell time only decreasing by a few minutes.

In summary, the trade-off between power and availability is not as severe as it may seem:

- Customer feedback is clear that charger availability is more important than the speed of the chargepoint;

- 350kW chargepoints only benefit the small market segment of luxury EVs, but their main impact is a reduction in the number of chargepoints that can be installed in any location;

- For those EVs that can utilise ultra-high-power chargepoints, charging at over 250kW is only sustained for a brief period, resulting in a minimal reduction to charging time.

Dwell time.

The discussion above assumes that the driver wants the fastest possible charge so they can continue their journey as we see at ‘en-route’ sites such as motorway service areas.

However, this is not the case for all EV charging locations. In ‘destination’ locations such as supermarkets, shopping centres, food outlets, etc, the charge power should be selected to provide the required charge over the desired dwell time at the site. If our Porsche Taycan example visits a cafe and spends 45-minutes having a coffee and bite to eat, it only requires a 75kW charge rate to charge from 20-80% in that 45-minute period.

Dynamic power distribution.

There is another solution at play. Dynamic load-balancing technology allows for a compromise between high-powered charging and higher numbers of chargepoints. It involves the intelligent allocation of available power across multiple charging units based on real-time demand. Using the example of our four 300kW chargepoints above, we can install even more chargepoints to deliver out the previously wasted 412kW of power. The power that was previously wholly allocated to one chargepoint, can now be moved between chargepoints based on which cars require what level of power throughout their charging time.

The dynamic load-balancing allows for the simultaneous charging of multiple vehicles while avoiding overloading the grid infrastructure. By dynamically managing the power allocation, EV charging networks like Osprey can maximise the installation of chargepoints while still allowing for high-powered charging.

So what is the answer for EV charging?

As one of the UK’s largest and fastest-growing public rapid-charging networks, 2024 and beyond is seeing Osprey Charging installing sites with as many units as the grid allows, but at the right charge rate. This sees us installing hubs with 300kW dynamic load-balancing chargepoints at En-Route sites with a short dwell time, through to 60-75kW units at Destination sites with an hour dwell time.

As we see more BEVs hitting our roads in the coming months and years, Osprey and the other charging networks have the responsibility to ensure we configure sites correctly to enable as many vehicles to charge as possible, so we can truly achieve the transition to net-zero.

The Osprey network will always be open to all drivers making the transition to EVs, with 100% of units offering contactless card readers, and the added flexibility of RFID and app access for those drivers who want VAT receipts and statements on hand. But Osprey are also pioneers in roaming partnerships, being founding launch partners of the Octopus Electroverse, Zap Pay from ZapMap, and both the Allstar and Paua fleet roaming programmes. It is for these reasons that Osprey is continually voted by EV drivers as one of the most-loved networks in the UK, renowned for its reliability, ease of use, and the quality of sites.

Harry Bleasdale

After completing his Master’s degree in Mechanical Engineering at Loughborough University, Harry was first introduced to the EV charging sector during an internship with Investec Bank in 2018, who had recently completed an initial investment in Osprey Charging (formerly Engenie). He went on to work for an industrially focussed Strategy Consultancy whilst continuing to keep a close eye on the rapidly developing UK EV market. By the end of 2019, the market and green revolution had drawn Harry back as he joined the Osprey team full-time to help reach their ambitious objectives during their rapid expansion. Now, Harry continues to develop Osprey’s commercial proposition and builds exciting strategic partnerships with key UK and European brands to drive Osprey’s utilisation and the UK’s switch to a sustainable transport future.

More Insights

See the latest insights from the Osprey Charging team